The Logan/Hotel Indigo

BACK IN SERVICE

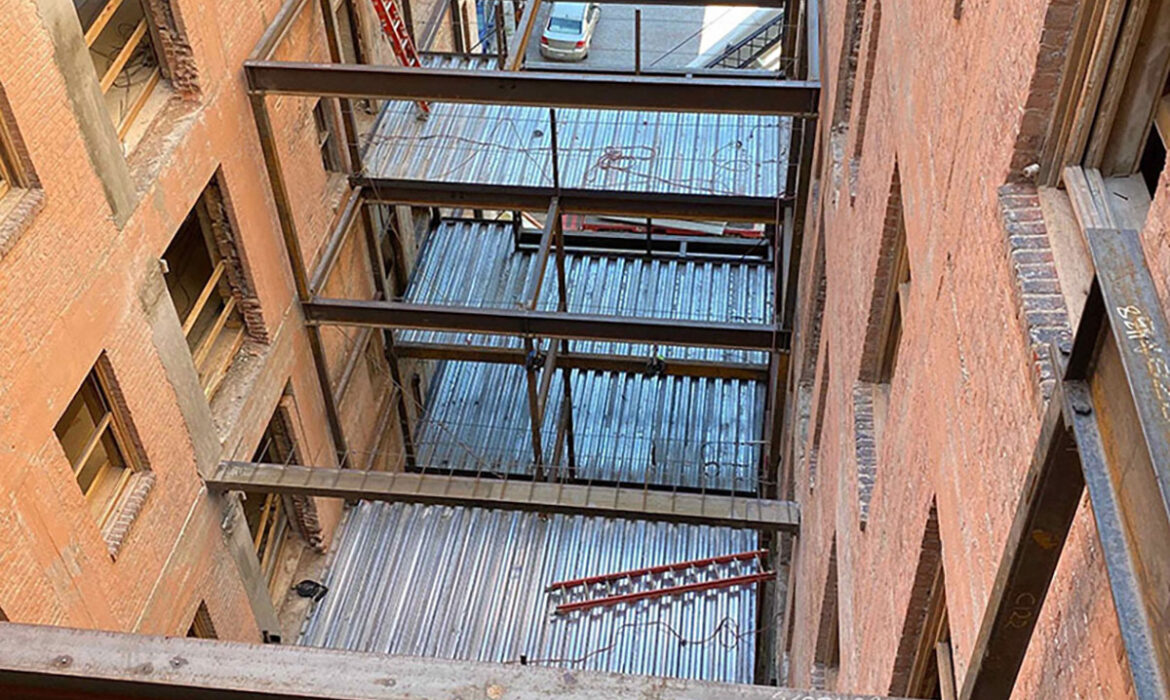

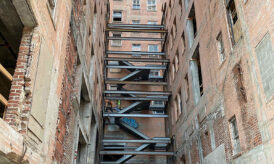

The Logan, a historic building in downtown Omaha, has been reborn into Hotel Indigo. The 7-story, 1918 brick landmark is back in service and features the innovative application of a structural foundation beneath two stair towers and an elevator tower placed into the narrow “U” shaped structure.

Developers envisioned the historic structure as a hotel, condos, and mixed-use (restaurant and office) commercial space. To accomplish the vision, the building needed an efficient way to move guests and residents to the upper floors and safe egress in the event of fire and emergency. But where? An internal marble staircase didn’t meet current code requirements. Fortunately, the flat-roofed “U” shaped building, with the open end facing north, provided the perfect location for the stairs and elevator towers.

With the location determined, the challenge became finding a low-vibration, deep foundation system in the limited space between the wings of the existing 7-story structure. The original foundation system was unknown.

Foundation Solution

An innovative application of technology was found using Ductal Iron Piles (DIP) to support the elevator and stair tower foundations. This technology, used mainly for oil drilling, is the first application in Omaha for this purpose. Sixteen End Bearing Ductile Iron Piles provided a low-vibration, deep foundation system. And proved to be a cost-effective confined space solution while providing the required structural strength and minimized settlement. DIP was installed rapidly to depths beyond 90 feet. And It was quickly mobilized to the site compared to more extensive piling operations.

STRUCTURAL HIGHLIGHTS

- The geotechnical report recommended structural loads of the stair towers and the elevator tower be supported on a deep foundation system. It offered the possibility of drilled foundations (ACIP piles and micro piles) or helical piers. However, the site was tight at 20 feet, with limited space and access for large equipment and weak clay conditions. The developer/GC hired Ground Improvement Engineering, Inc. to evaluate alternatives. They learned of the Ductile Iron Pile option and developed a preliminary design approach. GIE and TD2 underwent multiple redesigns and plans showing 16 Ductile Iron Piles with 40 tons (compression) capacity. The final design used Series 118/90 Ductile Iron Piles (118 mm diameter with 9MM wall thickness). The plan required them to advance through the site clay to terminate by achieving “set” on bedrock to depths of 85 to 95 feet.

Photo Credit: Photos courtesy of NGC New Generation Construction.